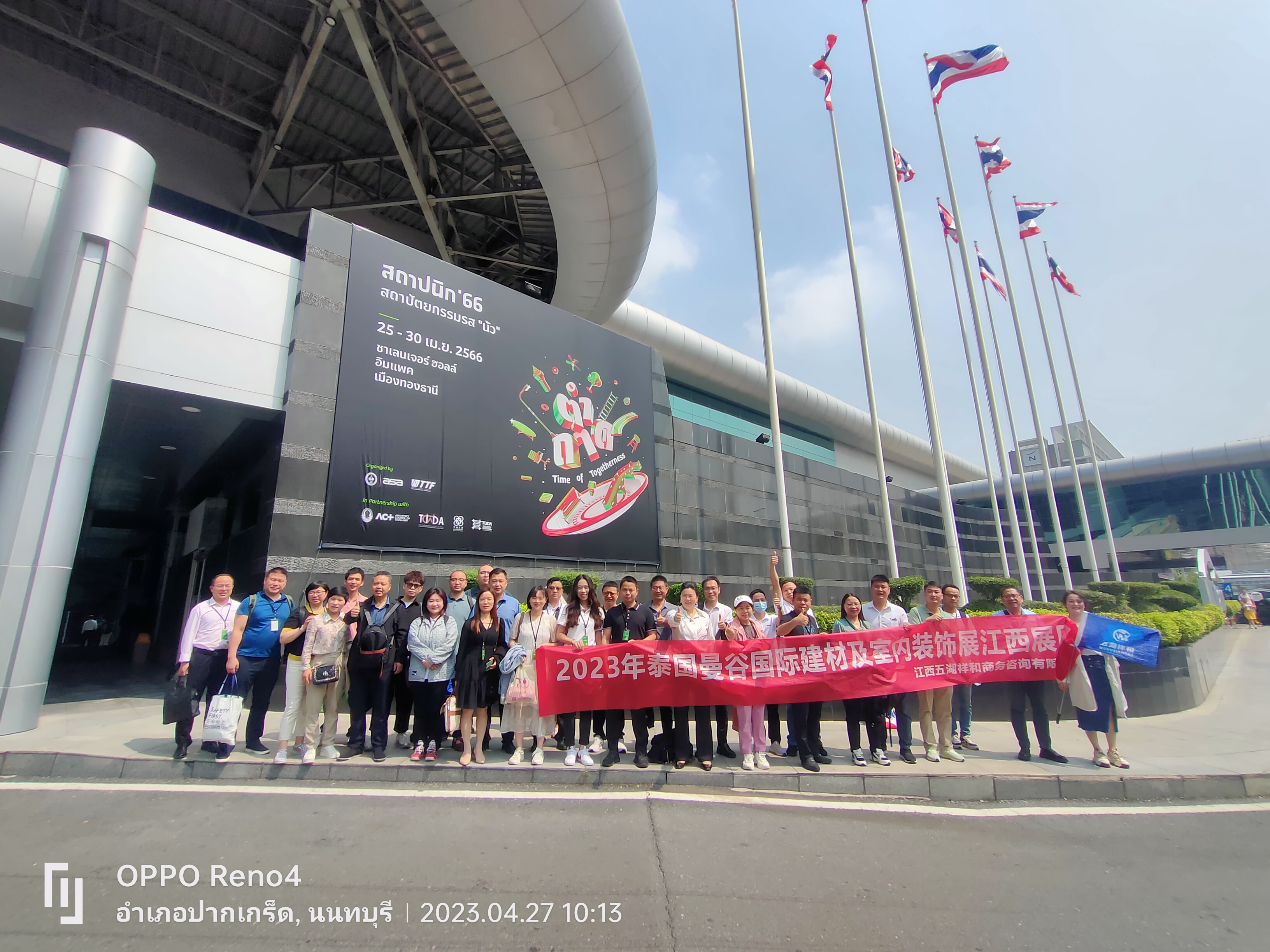

Socios empresariales

- 44añosFundada en 1979

- 800Equipos CNC y centros de mecanizado importados de Japón y Corea del Sur

- 120Proporcionando productos y servicios a más de 120 países y regiones en todo el mundo.

- 66000La base de producción cubre un área de más de 60.000 metros cuadrados.

Acerca deCXCREYENDO

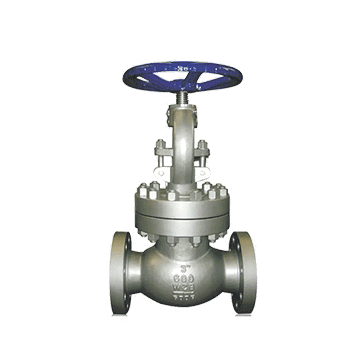

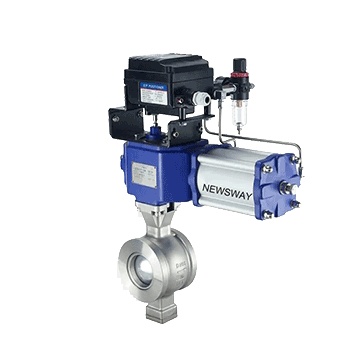

Jiangxi Mide Industrial Co., Ltd. se dedica a la producción y venta de diversas mesas elevadoras, polipastos, cabrestantes y piezas para grúas. Nuestra empresa, Mide, está ubicada en la hermosa ciudad de Nanchang, provincia de Jiangxi, China. Contamos con un excelente equipo de diseño de I+D y un sistema de control de calidad confiable, lo que garantiza la calidad de nuestros productos, a un precio muy competitivo. Contamos con las certificaciones del Sistema de Gestión de Calidad, ISO y CE. El objetivo de la gestión de Mide es pensar en las necesidades y deseos del cliente. La calidad define la marca y la integridad forja el futuro. Exportamos nuestros productos a países como Oriente Medio, Rusia, Asia, Europa, África, Sudamérica, etc.

sobre nosotros

010203040506

010203

010203